Lowering the total cost

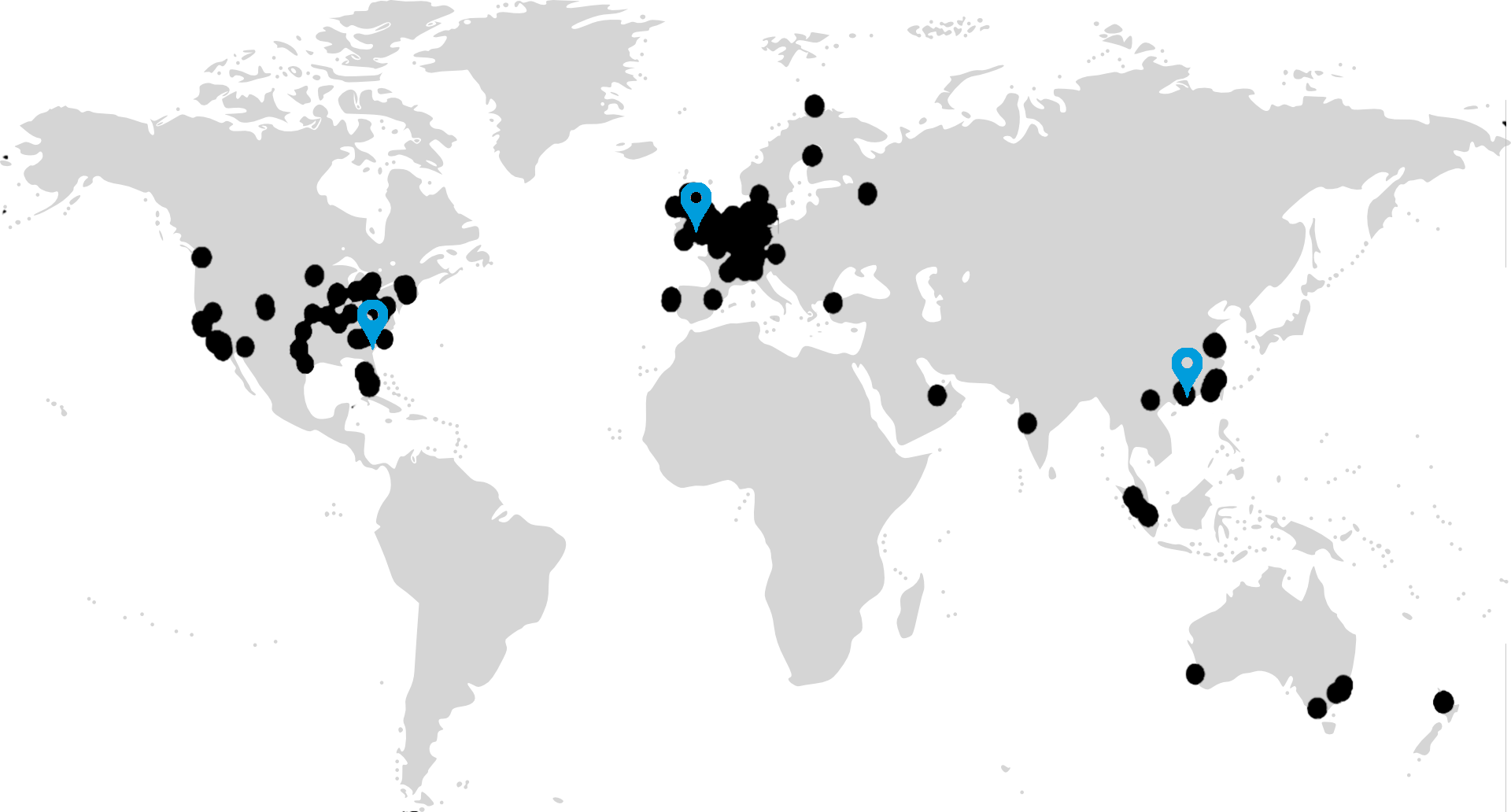

Our clients choose P2i because we have been lowering the total cost of ownership for our clients since 2004. Trusted globally, we have validated our technology with over 350 customers.

Compared to current methods of protecting electronics, P2i can deliver Better, Faster and Cheaper.

Through our molecular-based process we protect both sides of a PCBA to prevent edge effects and ensure 100% component underfill. This will maximise reliability whilst minimising masking costs.

The manufacturing solutions of either batch processing or continuous flow will ensure the lowest network latency and minimal WIP in factory.

Our solution delivery reduces factory floor space and associated electricity, lowers labour and process costs, eliminates scrap, allows conventional re-work and ensures reduced field failure returns. Combining all these delivers a lower total cost of ownership.

Benefits of Choosing P2i for the lowest total cost

Sustainability

Government regulations and global momentum are pushing industry to increase their carbon savings.

By protecting devices from liquid ingress and damage, product life-cycles will increase. This will draw less on the planet’s precious resources.

As an example, for a standard mobile phone, a reduction of over 1kg CO2eq per device can be achieved.

Partnering with P2i can enable our clients to reduce costs and increase sustainability.

Quality

P2i will maximise the performance reliability by protecting both sides of the PCBA.

By operating at the molecular level, edge effects do not occur.

100% component underfill results through the P2i patented low pressure process.

Cost

P2i’s conformal coatings deliver the lowest total cost of ownership. This includes maximising through-put, reducing scrap rates and miniming returns.

This approach to extend product lefe-cycles requires less materials and generates less waste. This has a positive effect on further reducing the total costs.

Integration

P2i remains very flexible and supports various business models:

In-Factory deployment:

Service Processing:

Where customers send products to P2i’s own facilities for contract processing. This provides a competitive service model for low-to-medium volume and quick-start processing.

Partnership

We work with our customers to demonstreate we pass all required verification trials.

The cusotmer shares with us in advance the required evaluation criteria to qualify for mass production.

Our Applications team select the required treatment stratgey to meet the goal. We then align with the cusotmer before treating the samples for customer evaluation.

Innovation

Our team continue to improve our coating capabilities to acheive the lowest costs for our customers. This includes a combination of the coating materials, coating thickness and equipment delivery.

The efficiency in mass production for our cusotmers is equally important and also drives our innovation.

Application Technology

- Operates at low pressure – penetrates complex 3D structures to maximise quality.

- Uses an ionization technique – creates durable bonds to minimise material use.

- Pulsed plasma mode – acheives the desired protection properties over the entire product.

P2i Support

Our global Service & Support Team ensures the efficient operation of the coating solution.

Our connected approach ensures the right level of support at the intended times.

Customer Validations of Lowest Total Cost

P2i works with OEMs and their Contract Manufacturers to deliver cost savings. Most cusotmers are looking for ways to outperform their competition at a lower cost. P2i’s unique, patented technology allows both of these to be realised. We are proud to partner with leading manufacturers including: